How Our Products Are Designed: The Creative Process Behind Every Piece

Share

Designing the perfect product isn’t just about having a vision—it’s about bringing that vision to life using the right tools and technology. At B1GSHOT, every piece we create goes through an extensive digital design process before it ever reaches production. Our design workflow involves three powerful software tools: Blender, CLO3D, and Photoshop. These tools allow us to craft detailed, high-quality designs that ensure each product meets our standards of aesthetics, fit, and functionality.

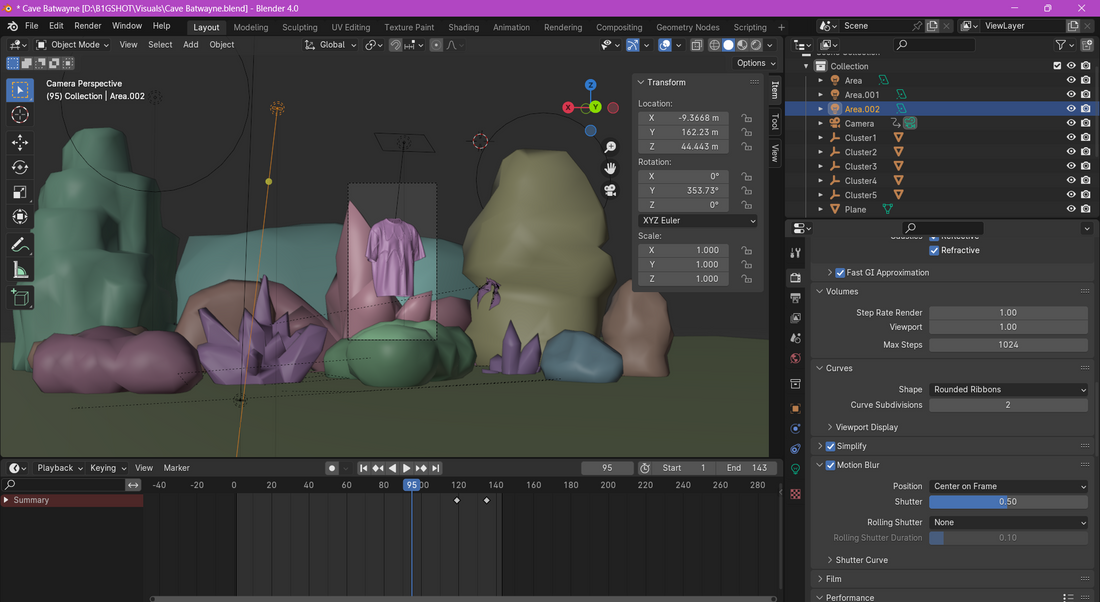

Step 1: Conceptualizing & 3D Modeling in Blender

The journey begins with Blender, a versatile 3D software that allows us to create highly detailed models of our products. Here’s how we use Blender in our design process:

-

Creating Base Models – We start by sculpting a rough 3D shape of the product, whether it’s a t-shirt, a pair of pants, or a hoodie.

-

Refining Details – Blender’s powerful tools help us add intricate details like fabric folds, seams, and other realistic textures.

-

Realistic Proportions – Using Blender ensures that our designs are proportionate, ensuring a proper fit when they go into production.

Blender gives us complete creative freedom, allowing us to experiment with different shapes and materials before committing to production.

Step 2: Virtual Prototyping with Clo3D

Once the 3D model is ready, we move to Clo3D, a specialized software for apparel design. Clo3D allows us to simulate how fabric moves and drapes on the body, helping us achieve the perfect fit and style before even making a physical sample. Here’s why Clo3D is a game-changer for us:

-

Fabric Simulation – We can test different fabrics virtually, seeing how they fold, stretch, and interact with movement.

-

Pattern Creation – Clo3D allows us to generate precise patterns, which are later used in the actual manufacturing process.

-

Realistic Fit Adjustments – By testing designs on virtual avatars, we can refine proportions and make sure each size fits as intended.

This digital prototyping step eliminates the need for multiple physical samples, reducing waste and making our process more sustainable.

Step 3: Final Touches with Photoshop

After finalizing the virtual prototypes, we use Photoshop to enhance our product images and create stunning visual presentations. Photoshop helps us with:

-

Texture and Color Adjustments – We refine fabric textures and color variations to ensure accuracy in our designs.

-

Design Enhancements – Adding logos, patterns, and graphics to visualize how they will appear on the final product.

-

Marketing Mockups – Creating high-quality mockups for website listings and promotional material.

With Photoshop, we ensure that our products not only look great in concept but also stand out in the market with eye-catching visuals.

From Digital to Reality

Once our designs are finalized in Blender, Clo3D, and Photoshop, they are sent to production, where skilled artisans bring them to life. This tech-driven approach allows us to create fashion-forward pieces with precision, efficiency, and sustainability in mind.

At B1GSHOT, we blend technology with creativity to craft products that don’t just look good—they feel amazing too. Every stitch, fold, and design choice is made with careful consideration, ensuring that you get the best in both style and quality.

Stay Tuned for More!

We are constantly innovating and refining our design process. Stay connected with us for behind-the-scenes insights, exclusive product drops, and more updates on how we bring our creative visions to life!